DESIGNER CNC MACHINE

2010-2024, Rama Hoetzlein

Overview

A computer-numeric control machine (CNC) is a milling machine that can carve into materials. CNC machines are subtractive whereas 3D printers are additive, yet CNC machines predate 3D printers and are capable of working with much more durable materials like wood and metal. This large-scale CNC machine was designed to carve artist-scale deep reliefs in 3D. This machine was built with a cutting area of 10×8 ft, and depth travel of 18″, and an accuracy of 1 mm. When I started this project in 2010 no such machines existed for less than $10,000. While similar machines can now be found for $4000 this CNC has a larger travel area at a quarter of the cost.

Design goals included the following:

1. Large-scale – The design uses a flying gantry with an independent table that allows for cutting of works of any depth, with easy change out of materials. The machine is large enough to cut a full sheet of 4 x 8 ft plywood.

2. Deep relief – A key design feature was to cut deep relief into foam for wax casting. The GiantCNC uses a 36″ lead screen to provide up to 18″ of Z-axis travel, with a unique fin-shaped mount for lateral stability. To keep down costs, cabinet slides are used for guide rails.

3. Low cost – The total cost of the machine is about $800, and is the lowest cost CNC machine for its size. Costs were reduced by using LVL lumber instead of steel, drawer slides for the Z-axis, lightweight chain, and common L-stock aluminum for X/Y-axis rails. Other costs were reduced with a special bearing box which allows the use of the same 1″ bearings throughout the machine.

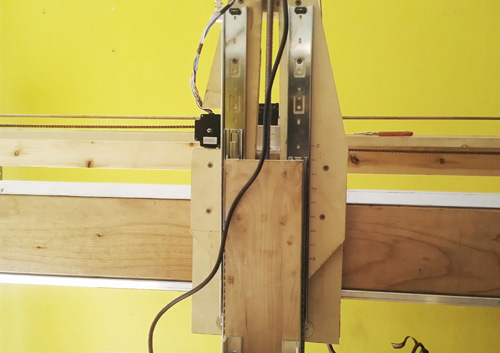

VERSION #1 – 2010-2012

The first version of the CNC Machine was created from 2010 to 2012 in the basement of my friend Mark’s house. This CNC machine features the large format, overhead boom, and chain drive. During this time tried and discovered that motorcycle chain was too heavy, leading to large oscillations, and shifted to lightweight chain. Unequal driving on the boom ends could cause wedging, where this was resolved by placing a dual-end Y-axis drive motor in the center with rods running to boom end gears.

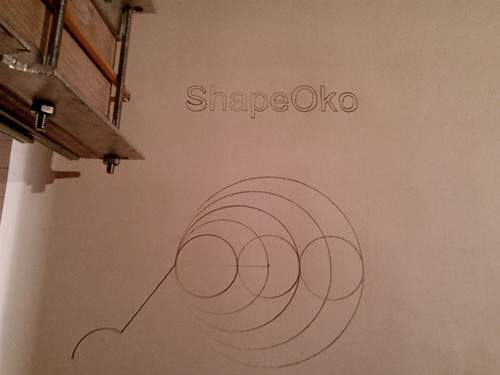

First run was achieved on Aug 6th, 2012. A standard shop router was mounted to the Z-axis, and two circles were cut using a 1/2″ flat end mill. The speeds and feeds were way off, causing the darkend (burnt) wood, and several bits to break off during initial attempts. Testing with a pencil allows for greater control, and demonstrates the precision of the machine despite its size. Here it draws a standard g-code pattern and text for ShapeOko.

The first project was created on Sept 28th, 2012, for the Ithaca Generator makerspace, a new make and build space located in Ithaca, NY. This was a test in laminated plywood, hence the change in color at different depths. G-code errors still presented a challenge to completing the pattern.

Created from a pencil drawing original, and converted to paths using Adobe Illustrator.

True depth relief from a 3D rendered model. The original model was designed in 3D in Maya (software). A depth map was rendered to produce a continuous tone black-and-white image representing depth. From this, the g-code tool path was generated using custom software. This produced the green tool path shown in the image, which is the path the CNC tool must take to reproduce the original 3D model. Finally, the g-code was cut in one run into oak hardwood to a relief depth of 1/4″, with a horizontal accuracy of 1/32″ using a 1/8″ end mill.

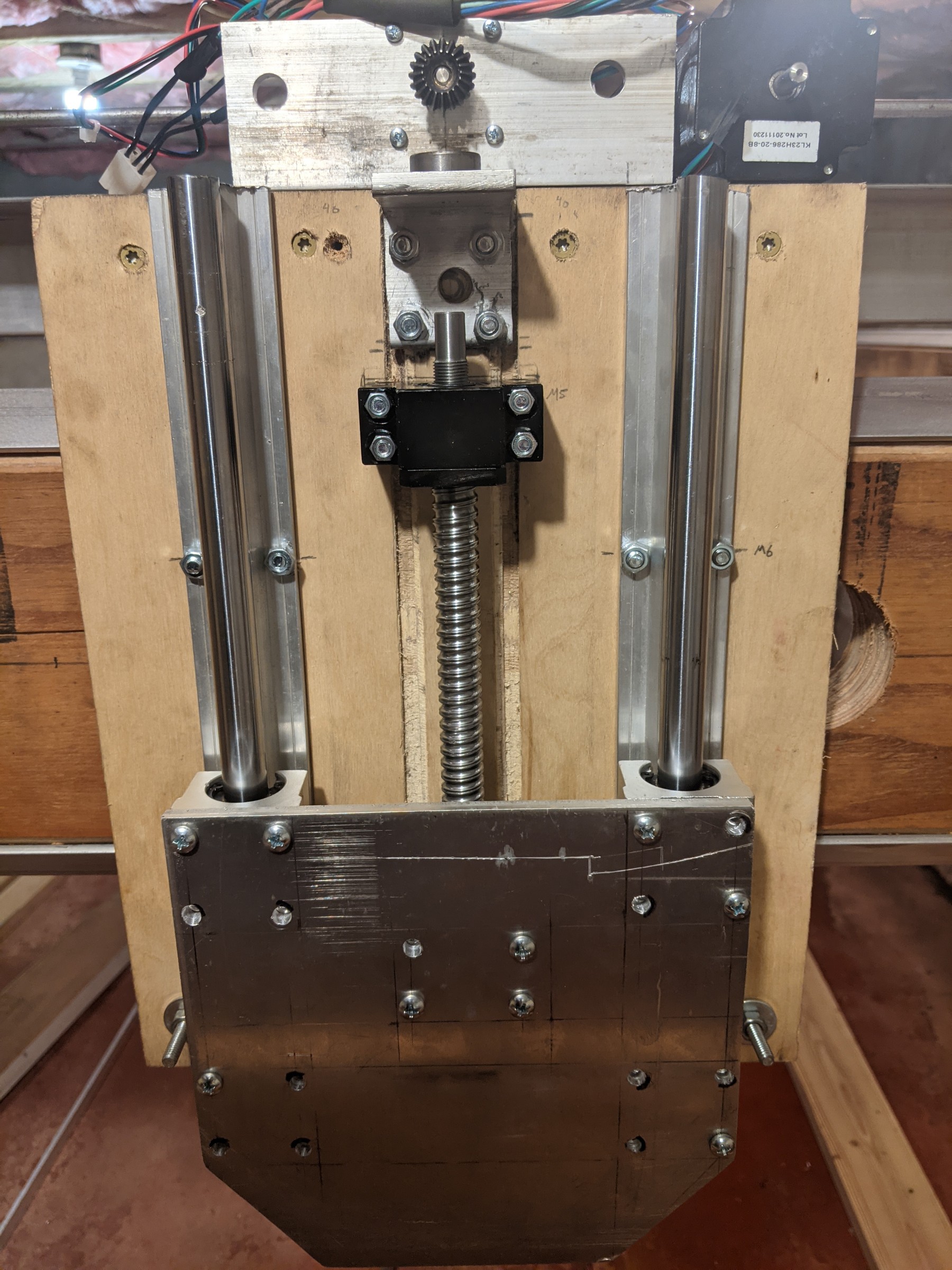

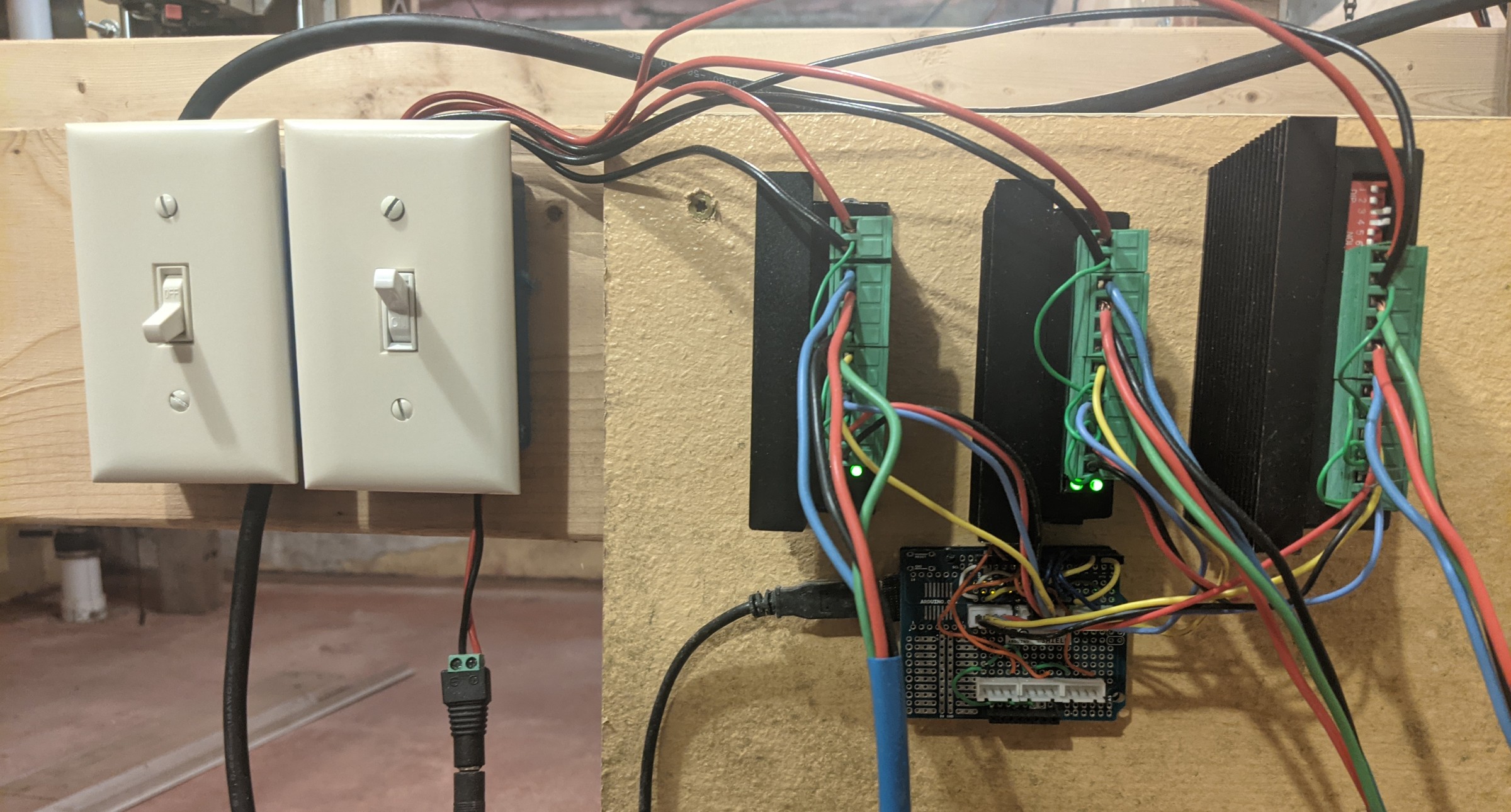

VERSION #2 – 2021-2024

The final version, Designer CNC, was rebuilt in 2021 in a new location with many of the same features. The dimensions are the same with chain drive for X and Y-axes. The most significant change was a redesign of the Z-axis using a lead screw and bearings, for smoother motion, with 90-degree bevel gears so that the Z-axis motor mass is closer to the axis. The motor driver controllers have been upgraded, and the software updated to Grbl running on an Arduino Uno.

416 South. Carved in 2021. This machine is capable of sign design using V-bits. The design was created in Adobe Illustrator, exported to stl and converted to g-code.

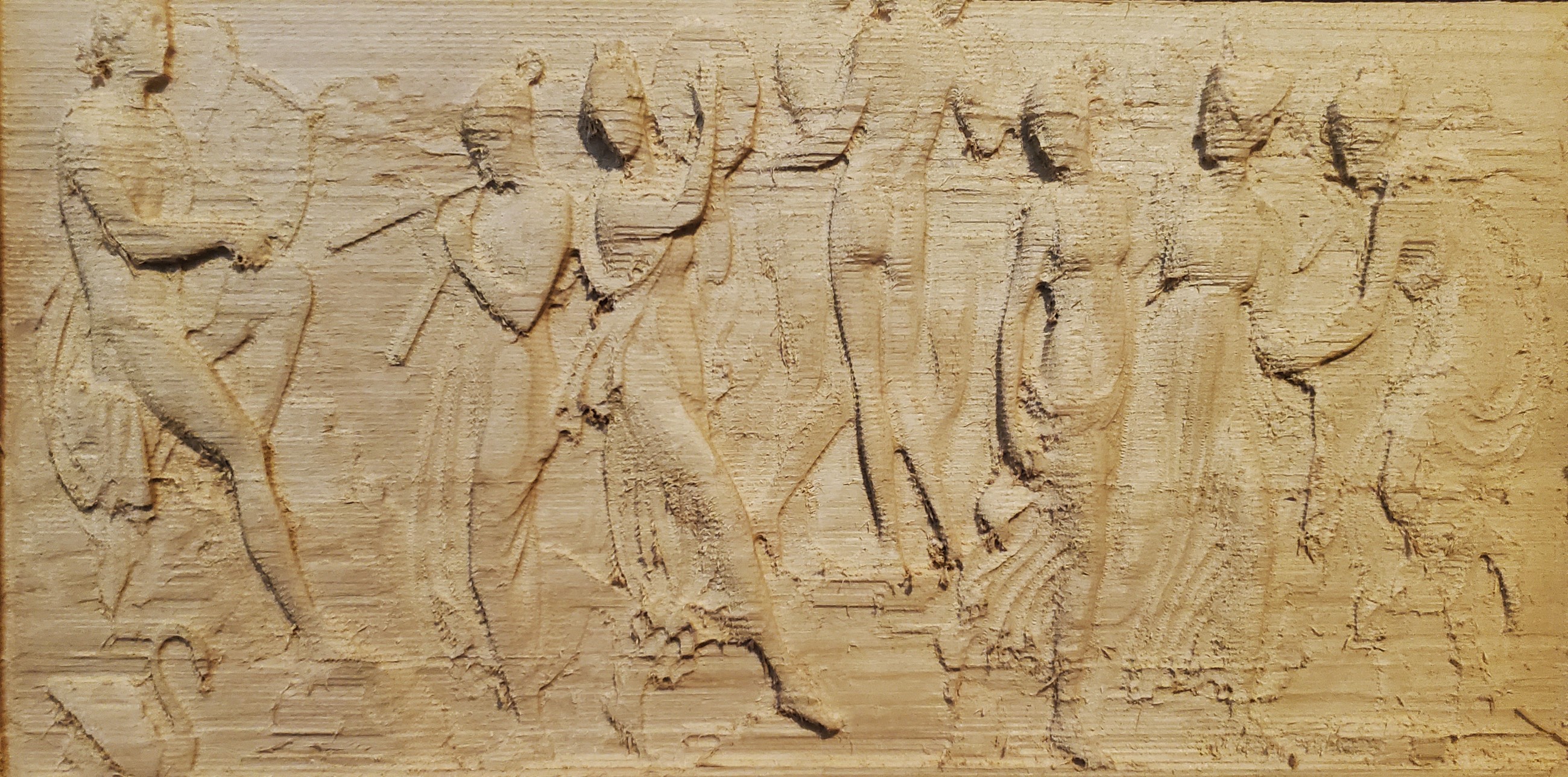

Renaissance Relief. Carved in 2023. I finally achieved the goal of highly detailed, 3D deep relief. Since the detail needed exceeds most existing img2gcode software, I had to write my own custom software to convert a 16-bit depth map to g-code, and then stream the g-code to the machine. The new software supports multiple passes for 1/4″ rough and 1/8″ fine carving. I hope to remove the final striations with a third pass and a 1/16″ ball-end bit.

Contact: ramahoetzlein @ gmail.com